What is Thermal Imaging?

This method involves identifying or generating an image of an object by detecting the heat it radiates. It goes by various names, including infrared imaging, thermography, and thermal scanning.

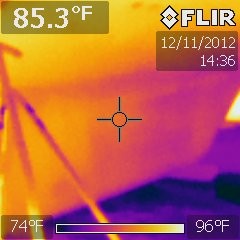

The picture depicts a Cummins diesel marine engine in operation during a sea trial. On the left, you see a conventional thermal image, while on the right, there’s a Thermal MSX® Image for comparison.

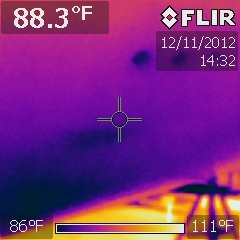

On the left, you can see a thermal image of the hull, while on the right, there’s a Thermal MSX® Image.

As seen in the images above, MSX® technology results in a sharper and more pristine thermal image, which simplifies the task of identifying issues.

What is the significance of this, and why does it matter?

As you may already be aware, marine surveying is a non-intrusive process. This means that surveyors do not need to disassemble components for internal inspections. Instead, they rely on observation and listening to compile survey reports. The integration of thermal imaging technology enhances the surveyor’s capabilities by allowing non-invasive internal inspections of components. In the past, examining the inside of components during a marine survey required the presence of a mechanic or technician. However, thanks to thermal imaging, our surveyors can peer inside components such as alternators, electrical panels, and power steering pumps, gaining a better understanding of the condition of bearings, including identifying excessive wear or misalignment. Without thermal imaging, surveyors may miss pending issues.

Thermal scans are particularly useful for identifying potential problems with components like engine cooling system heat exchangers, bearings, manifolds, and risers, among others. This technology enables surveyors to detect coolant obstructions in the engine and uncover potential issues that might otherwise go unnoticed without the expertise of a marine mechanic or electrician. This doesn’t mean we discourage working with electrical and mechanical professionals; their expertise remains invaluable. What we are emphasizing is that the use of thermal imaging enhances our ability to perform our duties effectively.

How Thermal Imaging Works

Thermal imaging stands out as the most effective tool for identifying temperature irregularities within machinery and electrical equipment. This technology can be applied to various materials, including wood, aluminum, steel, and fiberglass, since all objects emit some degree of thermal radiation. What sets thermal imaging apart is its ability to function in total darkness, in contrast to night vision devices that rely on ambient light.

Across various industries, thermal cameras have proven their worth in assisting with equipment maintenance and repair. In particular, the application of thermal imaging has been prominent in the evaluation of commercial aircraft systems and hulls. Although relatively new in the field of marine surveying, at Sun Coast Marine Surveying, we are committed to equipping our surveyors with the finest tools to enhance their service to our valued clients.

Thermographic cameras have a striking resemblance to portable digital video cameras, and they operate in a similar fashion, with the notable distinction that thermal cameras utilize thermal imaging technology. At our company, we exclusively utilize FLIR® brand infrared cameras, specifically opting for FLIR® cameras that incorporate the distinctive MSX® technology. It’s important to note that MSX® technology is an exclusive feature found only in FLIR® cameras and is not present in all FLIR® camera models. MSX® technology seamlessly integrates critical details from the built-in visible light camera in real-time. The end result is a thermal image enriched with labels, numbers, and even structural features, greatly facilitating the identification of the object under inspection.

When a target item emits infrared light, a dedicated lens focuses this light onto an infrared camera. In the case of MSX® technology, an additional lens on the camera captures digital photos, enabling the creation of three distinct images of the target item:

1. Digital Image 2. Thermal Image 3. Thermal MSX

The thermal MSX® image is a composite overlay of the three images, resulting in enhanced clarity and ease of recognition. These composite images are viewable through the FLIR® software.

Advantages of Thermal Imaging?

Thermal imaging offers numerous advantages, particularly in the field of marine surveying, including the following key benefits:

- Contactless Inspection: Thermal imaging ensures that surveyors never need to make physical contact with hot and moving engine-room components, enhancing their safety. Furthermore, it allows the inspection of electrical components without the risk of electrocution.

- Real-Time Analysis: Scanning and recording with a thermal camera occur instantaneously, eliminating any time wasted in generating images.

- Visualizing Thermal Patterns: This feature is invaluable as it reduces the need to hire a mechanic or technician during a boat inspection, saving time and money for clients while expediting the surveyor’s work. Temperature irregularities are easily identified through thermographic images.

- Enhanced Survey Reports: At Sun Coast Marine Surveying and Consulting, we offer thermal imaging at no additional cost. We employ it to gain a better understanding of various components, including electrical systems, tanks, gearboxes, engines, hulls, and decks. Thermal imaging enriches our insight into potential issues or faults.

Thermography and How It makes Your Vessel Safer

Absolutely, thermography is a resounding yes when it comes to enhancing vessel safety and investment. This technology not only identifies existing issues but also pinpoints potential future problems. This valuable information secures your vessel as a safer and more reliable investment.

Thermography’s capabilities extend to detecting abnormal heat patterns that might lead to electrical fires and identifying water or gasoline leaks from tanks, averting water damage and potential explosions. In the engine, thermal imaging is instrumental in identifying temperature irregularities that could otherwise result in costly repairs.

In the image on the right, delamination was successfully identified using thermography. As demonstrated, thermal imaging empowers surveyors to uncover structural issues that might remain concealed using traditional surveying methods.

While we embrace new technologies that transform our practices, at Sun Coast Marine Surveying and Consulting, we continue to rely on tried-and-true traditional surveying techniques, including percussion soundings and the GRP33 moisture meter. Our utilization of FLIR® thermal cameras equipped with MSX® imaging technology allows us to offer more comprehensive surveys, setting us apart from our competition.

Thermal image of a onboard generator operating under a load.

Thermal image of a Cummins Diesel engine

Infrared thermal image of hull delamination on the lower right side of the image.

Infrared thermal image of a hull bottom with hidden delamination under the fiberglass